-

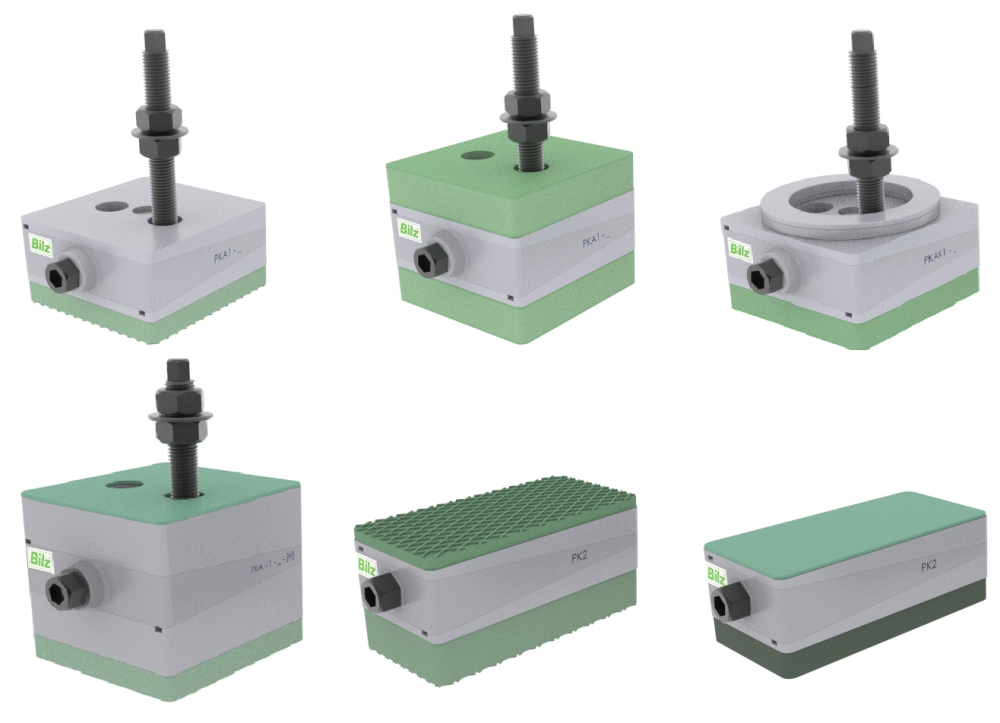

BILZ Precision Wedge Mounts

-

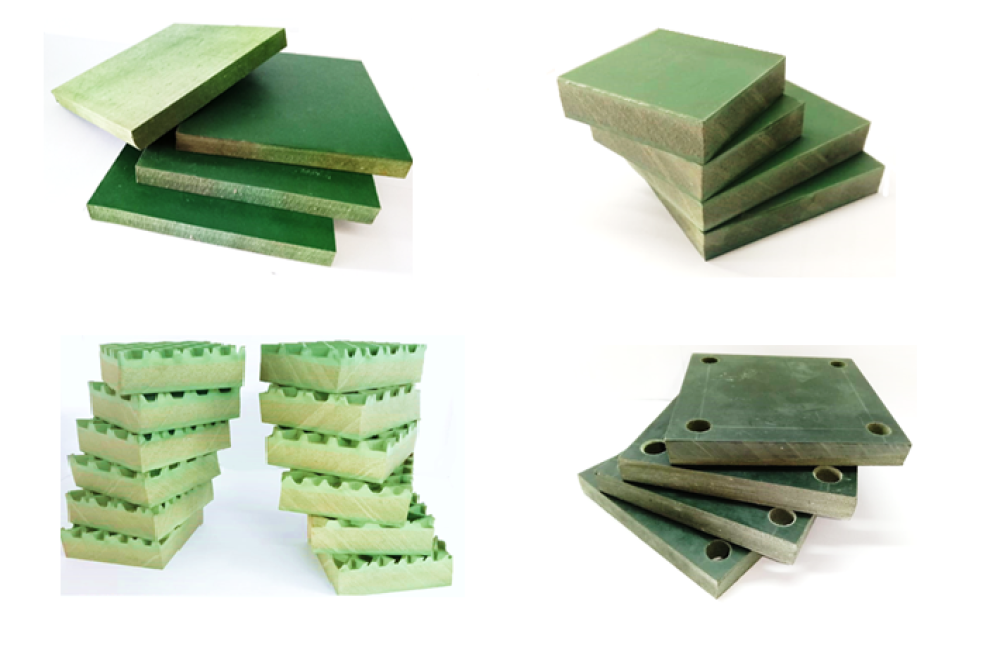

BILZ Antivibration Green Plates

-

BiAir Membrane Air Springs For Sensitive Machines

-

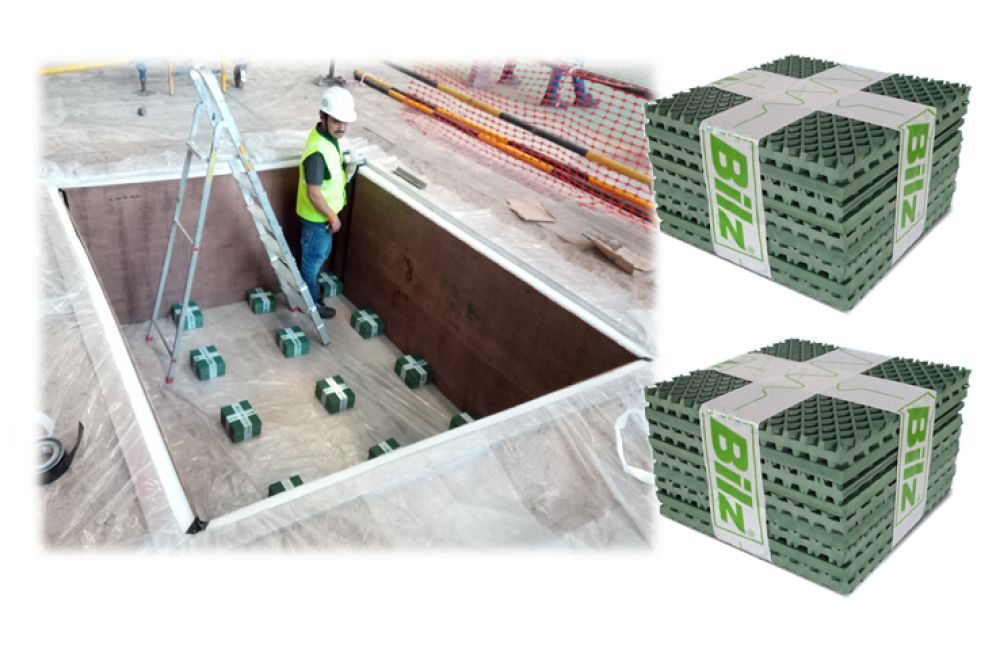

Isolation Foundation For Sensitive & Heavy Machines

-

Perma Automatic Grease Lubrication Systems

-

Perma Battery Operating Systems

-

PAX

-

Samoa Product Application

-

Industrial Shock Absorbers

-

TUBUS Profle Dampers

-

Thermosonics - Creating Sound Proof Industrial Environment